GET IN TOUCH

2873 Kingsview Blvd SE, Airdrie, AB, T4A 0E1, Canada

+1 (403) 948-6464

info@gncorporations.com

Monday to Friday 8 a.m. – 4 p.m.

Saturday & Sunday: Closed

(GMT -7 Mountain Time)

FULL SERVICE. FULL CONFIDENCE. COMPLETE SOLUTION.

DISCOVER THE POWER OF DATA-DRIVEN MANUFACTURING

Advanced manufacturing for the Aerospace, Automotive, Defense, Oil & Gas, & Technology Industries

FULL SERVICE. FULL CONFIDENCE. COMPLETE SOLUTION.

DISCOVER THE POWER OF DATA-DRIVEN MANUFACTURING

Advanced manufacturing for the Aerospace, Automotive, Defense, Oil & Gas, & Technology Industries

Imagine

a better, more streamlined manufacturing process.

Collaborate

with a leader and strategic partner in digital manufacturing who goes above and beyond to guarantee your success.

Create

and build high quality products with CNC machining powered by advanced technology.

OUR MANUFACTURING SERVICES

-

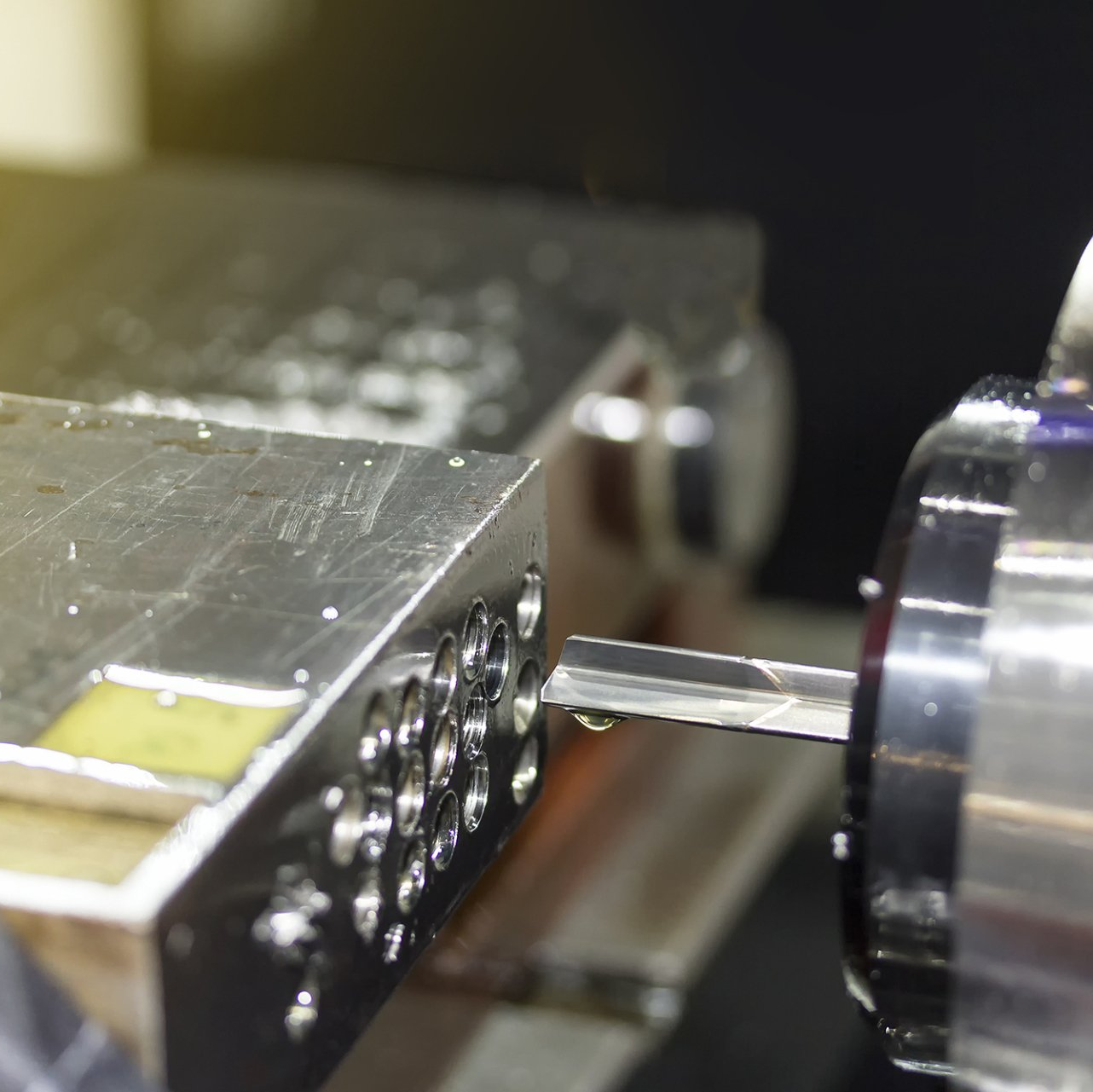

CNC MACHINING SERVICE

Learn MoreGN’s fully automated CNC machining services allow your company to benefit from our leading-edge GN 4.0 platform — leveraging machine learning and automation to deliver a new level of quality and precision.

-

DEEPHOLE & GUN DRILLING

Learn MoreGN uses industry-leading tools and technologies to provide reliable, precise deep hole and gun drilling services. We’re ready to work with various materials, from stainless steel to special alloys.

-

WATERJET CUTTING

More On Waterjet CuttingSome fabrication methods can risk the integrity of the material by weakening the surface near cuts. Our Tier-1 waterjet cutting service is designed to maintain the strength of any material we work with, so you can get the cuts you need.

-

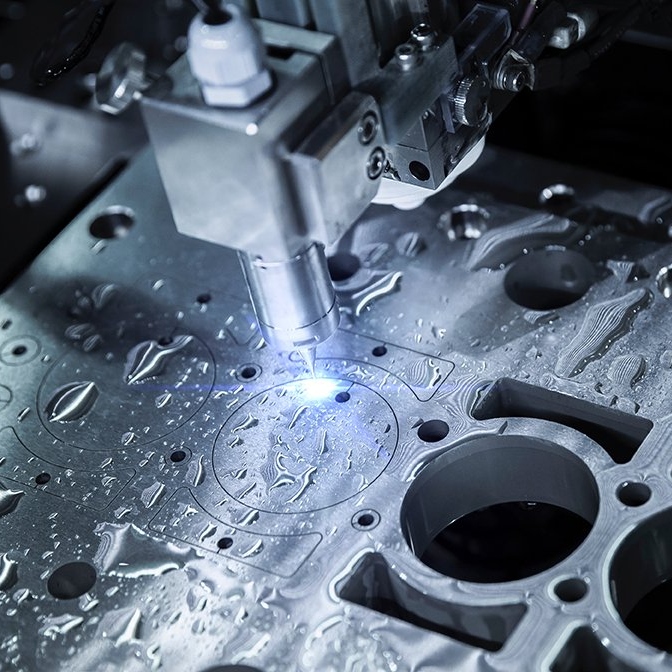

WELDING/BRAZING/HARDFACING

More On Welding & BrazingOur CWB-certified welding, brazing, and hardfacing services leverage the latest advancements in machine learning and automation to provide unparalleled results. In addition, our GN 4.0 technology provides advanced accuracy with every action.

-

ASSEMBLY SERVICES

More On Assembly ServiceWe are a Tier-1 supplier of dependable assembly services ready to take on all manufacturing phases, from your prototype to final production. Our high-precision equipment and quality-first approach ensures your final product meets or exceeds your expectations

-

ALL MANUFACTURING SERVICES

View AllView all of our manufacturing services

OUR PROCESS

GN follows the Production Part Approval Process (PPAP), which is a standardized process that involves approval of production designs and processes before, during, and after manufacturing.

SAY HELLO TO

GN 4.0 Smart Factory

The new industrial revolution is here. Here’s how we’re leading the way. Advances in artificial intelligence, machine learning, and connected technology have fundamentally disrupted manufacturing. Automation and digitization together enable greater efficiency, visibility, and control across the entire supply chain. It's an evolution on par with the birth of machine manufacturing — and GN is at the forefront.

The advanced technology that GN uses is designed around Industry 4.0 and delivers high precision and cost competitive manufacturing for differing volumes of production. This allows GN to be globally competitive and ensures our customers competitiveness and ability to obtain more of their respective market.

OUR INSIGHTS

WHY PARTNER WITH GN?

With over five decades of experience in the manufacturing sector, GN Corporations is a turnkey, tier 1 supplier serving some of the most complex industries in the world. But we're more than just a supplier — we're a strategic partner.

When we work with a business, we go above and beyond to guarantee their success.

ADVANCED GN 4.0 TECHNOLOGY

Ensure higher precision and lower costs throughout production using our data-driven GN 4.0 platform, advanced CNC machining, and automation technology.

HELPFUL LINKS

INDUSTRIES

SERVICES

CONTACT

2873 Kingsview Blvd SE, Airdrie, AB, T4A 0E1, Canada

+1 (403) 948-6464

info@gncorporations.com

Monday to Friday 8 a.m. – 4:30 p.m.

Saturday & Sunday: Closed

(GMT -7 Mountain Time)

MANUFACTURING INDUSTRY CERTIFICATIONS

All Rights Reserved | GN Corporations Inc. | Industry Certifications Include: ISO 9001:2015, AS9100D:2016, ISO 14001:2018, ISO 45001:2018 | In Partnership with CCC